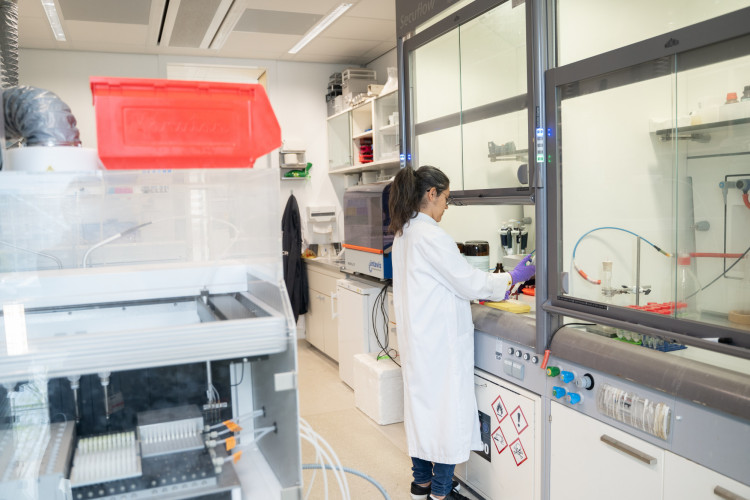

Each year, the facility synthesizes peptides for both internal researchers and external partners in academia and industry. Our expertise and advanced instrumentation enable us to go far beyond standard peptide synthesis, offering custom-made peptides with complex sequences and unique modifications. We support both small-scale, project-specific synthesis and routine, semi-large-scale production.

Close integration with the multidisciplinary research of the Mulder, van der Heden & Geurink labs allows us to continuously innovate in synthesis, purification, and analytical techniques—ensuring flexibility, high quality, and responsiveness to evolving scientific and commercial needs.

Synthesis of Specialized Peptides

In addition to standard peptides, the facility also offers the synthesis of specifically modified peptides, including:

- Ubiquitin and ubiquitin-like proteins with sequences ranging from 76 to 100 amino acids, as well as related derivatives

- Peptides with side-chain modifications (e.g., thiolysine)

- Peptides incorporating non-natural amino acids

- N-terminal modifications, such as biotinylation, acetylation, and fluorescent labels (e.g., Cy5, TAMRA, Rhodamine)

- Phosphorylated peptides

- UV-cleavable peptides

- Alanine scans for studying sequence–function relationships

Technological Infrastructure:

Since the Peptide Facility is integrated within a research group with both organic chemistry and biochemistry expertise, it has access to a wide range of advanced equipment. This synergy enables the production of high-quality peptides tailored to the specific needs of both research and commercial applications. The facility routinely uses Fmoc solid-phase chemistry for peptide synthesis. The equipment includes three Syro II robotic synthesizers and an Intavis synthesizer equipped with real-time Fmoc monitoring.

- The Syro II synthesizers support parallel peptide synthesis with different capacities: one system typically synthesizes 48 peptides simultaneously at a 25 µmol scale, while the other can produce up to 576 peptides in a single run at up to 4 µmol, specifically for screening purposes.

- The Intavis synthesizer is used for producing larger peptide quantities and refining complex sequences, leveraging real-time Fmoc monitoring for advanced applications.

The facility also uses a range of equipment for quality control and purification:

Mass Spectrometers

- WATERS Acquity H-Class UPLC with LCT-Premier Mass Spectrometer

- WATERS Acquity H-Class UPLC with high-resolution XEVO G2-S QTOF Mass Spectrometer

HPLC Systems

- WATERS 2545 LC with a 3100 Mass Spectrometer; mass-triggered collection during HPLC purification

- WATERS 2535 coupled with a 2545 UV-VIS detector; routinely used for large-scale purification of ubiquitin(-like) proteins

- WATERS Acquity H-Class UPLC for peptide purity analysis

- Shimadzu LC-20 system; routinely used for small-scale peptide purifications (1–5 mg)

CONTACT

Cami Talavera Ormeno

E-mail: peptides@lumc.nl

Tel: +31 (0) 71 526 8730

.jpg)

Cami Talavera Ormeno

Peptide Facility

Department of Cell and Chemical Biology (CCB)

Leiden University Medical Center (LUMC)